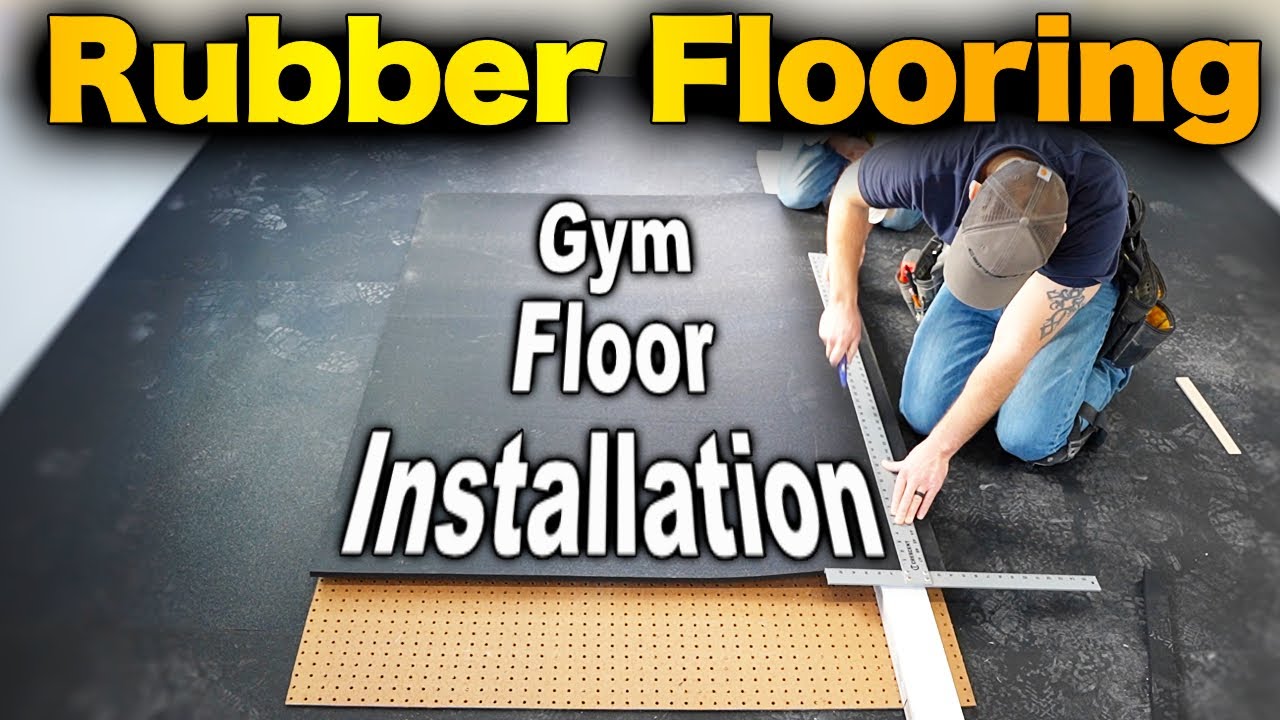

Can you install rubber gym flooring yourself? Absolutely! Installing rubber gym flooring is a manageable DIY project that can significantly upgrade your workout space, whether it’s a dedicated commercial gym flooring setup or your personal home gym flooring. This guide will walk you through the entire process, from choosing the right materials to the final touches. We’ll cover everything you need to know about installing rubber flooring, making DIY rubber flooring a straightforward success.

Image Source: i.ytimg.com

Why Choose Rubber Gym Flooring?

Rubber flooring is a popular choice for gyms and fitness centers for several good reasons. Its durability, shock absorption, and anti-slip properties make it ideal for high-impact activities.

- Durability: Rubber can withstand heavy weights, constant foot traffic, and the impact of dropped equipment.

- Shock Absorption: This protects your joints during exercises like jumping and lifting, and also safeguards your subfloor from damage.

- Noise Reduction: The dense nature of rubber helps dampen the sound of dropped weights and other gym noises.

- Traction: The textured surface provides excellent grip, reducing the risk of slips and falls.

- Ease of Cleaning: Most rubber flooring types are easy to wipe down and maintain.

- Comfort: It offers a more comfortable surface to stand and exercise on compared to concrete or hardwood.

Types of Rubber Gym Flooring

There are several popular options when it comes to rubber gym mats and tiles. Each has its own advantages and is suited for different needs.

1. Rolled Rubber Flooring

Rolled rubber flooring comes in large rolls, similar to carpet. It’s a great option for covering large areas quickly and offers a seamless look.

- Pros: Minimal seams, easy to cover large spaces, can be very durable.

- Cons: Can be heavy and difficult to maneuver, requires precise cutting for a clean finish, might need adhesive for stability in high-traffic areas.

2. Interlocking Rubber Tiles

Interlocking rubber tiles are a very popular choice for DIY installations. They come in various thicknesses and sizes and fit together like puzzle pieces.

- Pros: Easy to install without special tools, modular design allows for easy replacement of damaged tiles, good for custom-sized spaces, can be installed loose-laid or with adhesive.

- Cons: Seams can be visible if not fitted perfectly, some thinner tiles might not offer as much shock absorption.

3. Rubber Mats

Individual rubber mats are typically thicker and heavier than interlocking tiles. They are often used for specific areas like weightlifting zones or under cardio equipment.

- Pros: Excellent shock absorption and impact protection, easy to place and move, good for protecting specific areas.

- Cons: Can be heavy, may shift if not secured, more seams if covering a large area.

Planning Your Gym Floor Installation

Proper planning is key to a successful gym floor installation. Before you buy anything, consider the following:

Measuring Your Space

Accurately measure the area you intend to cover. This will help you calculate how much flooring you need and minimize waste.

- Length and Width: Measure the length and width of the room.

- Irregular Shapes: If your room has alcoves, columns, or other irregular shapes, measure each section separately.

- Add Extra: It’s always a good idea to add an extra 5-10% to your total to account for cuts, waste, and potential future replacements.

Choosing the Right Thickness

The thickness of your rubber flooring should depend on your intended use.

- Cardio & Light Weights (Home Gym): 1/4 inch to 3/8 inch is usually sufficient.

- General Weightlifting & HIIT (Home Gym/Small Studio): 1/2 inch provides better shock absorption.

- Heavy Lifting & Commercial Gyms: 3/4 inch or thicker is recommended for maximum impact protection and durability.

Subfloor Preparation

The condition of your subfloor is crucial for a successful rubber flooring adhesive application and overall longevity of your new gym floor.

- Concrete: The most common subfloor. It should be clean, dry, and free of cracks or major imperfections.

- Wood: Ensure the wood subfloor is stable and doesn’t have any loose boards. You might need to reinforce it if it feels spongy.

- Existing Flooring: If you have old carpet or linoleum, it’s generally best to remove it to ensure a clean, flat surface for the rubber.

Step-by-Step Installation Guide

Let’s dive into the actual installing rubber flooring process. This guide focuses on interlocking rubber tiles, as they are the most common DIY choice.

Step 1: Gather Your Tools and Materials

Before you start, make sure you have everything you need:

Materials:

- Rubber gym tiles (interlocking, rolled, or mats)

- Utility knife or heavy-duty scissors (for cutting tiles)

- Measuring tape

- Pencil or chalk line

- Straight edge or ruler

- Optional: Rubber flooring adhesive (if securing tiles)

- Optional: Spacers (for expansion gaps)

- Optional: Broom and vacuum cleaner

- Optional: Floor cleaner and degreaser (for subfloor prep)

Tools:

- Safety glasses

- Work gloves

- Knee pads

- Optional: Rubber mallet (to tap tiles into place)

Step 2: Prepare the Subfloor

A clean and level subfloor is essential for a professional-looking and long-lasting installation.

- Clean Thoroughly: Sweep and vacuum the entire area to remove dust, dirt, and debris. If the subfloor is particularly dirty or greasy, clean it with an appropriate floor cleaner and degreaser, then allow it to dry completely.

- Check for Levelness: Walk around the area. Are there any high spots or low spots? While minor imperfections are usually okay with thicker rubber flooring, significant unevenness can cause tiles to lift or seams to separate. For concrete floors, minor cracks can be filled with a concrete patch.

- Acclimate the Flooring: For the best results, especially with interlocking rubber tiles, let them acclimate to the room temperature for at least 24-48 hours before installation. This helps them expand or contract to their final size, reducing the risk of gaps or buckling later.

Step 3: Plan Your Rubber Tile Layout

This is where your rubber tile layout planning comes into play.

- Start in a Corner: Begin in the corner of the room that is least visible, or the furthest from the main entrance. This way, any cuts will be against the walls and less noticeable.

- Dry Fit: Lay out a few rows of tiles without interlocking them to get a feel for the fit and to visualize the overall pattern.

- Consider Doorways and Obstacles: Think about how the tiles will meet doorways, pillars, or other features. You’ll likely need to cut tiles to fit around these.

- Minimize Cuts: Try to arrange the tiles so that the cuts are on the edges of the room rather than in the center. This leads to a cleaner look.

- Use a Chalk Line (Optional): For a perfectly straight starting line, you can snap a chalk line across your subfloor.

Step 4: Installing the Interlocking Rubber Tiles

Now, it’s time to put the pieces together!

- Interlock the First Tile: Take your first tile and place it in the chosen corner.

- Connect the Next Tile: Take a second tile and align its interlocking edges with the first. Gently push them together. You might need to use a rubber mallet to gently tap the edges, ensuring a snug fit. Be careful not to hit too hard, as this can damage the interlocking mechanism.

- Continue Laying Tiles: Continue connecting tiles row by row, working your way across the room. Ensure each tile is firmly interlocked with its neighbors.

- Cutting Tiles: When you reach a wall or an obstacle, measure the space that needs to be filled. Transfer this measurement to a rubber tile using your pencil and straight edge. Carefully cut the tile with your utility knife. You may need to make multiple passes with the knife for thicker tiles.

- Tip: For intricate cuts around pipes or columns, you can create a paper template first, then transfer the shape to the rubber tile.

- Fitting Cut Pieces: Use the cut pieces to fill in remaining spaces along the walls.

- Check Seams: As you go, periodically check the seams between tiles. They should be tight and flush. If you notice a gap, gently tap the tiles together with your mallet.

Step 5: Securing the Flooring (Optional but Recommended)

For heavy use or if your tiles seem to shift, consider securing them.

Option A: Loose-Laid Installation

For most home gym applications with interlocking rubber tiles, a loose-laid installation is sufficient. The weight of the tiles and their interlocking nature usually keeps them in place. However, if you notice any shifting, especially in high-traffic areas or around the perimeter, you might want to use a small amount of double-sided tape or a specialized rubber flooring adhesive.

Option B: Using Rubber Flooring Adhesive

If you are installing in a high-traffic commercial gym flooring environment, or if your rubber gym mats are thinner and prone to shifting, using rubber flooring adhesive is recommended.

- Apply Adhesive: Follow the manufacturer’s instructions for the adhesive. Typically, you’ll use a notched trowel to spread the adhesive evenly across a section of the subfloor. Work in small sections so the adhesive doesn’t dry out before you lay the tiles.

- Lay Tiles into Adhesive: Carefully place the interlocking tiles into the wet adhesive, ensuring they are pressed down firmly to create good contact.

- Stagger Seams (if applicable): If you are using individual rubber mats, it’s good practice to stagger the seams, much like laying bricks, to create a more stable and seamless floor.

- Rolling the Floor: Once a section is laid, use a heavy roller (if you have one) to press the tiles down firmly into the adhesive. This ensures maximum adhesion.

- Allow to Cure: Let the adhesive cure completely according to the manufacturer’s instructions before allowing any heavy use or placing equipment on the floor. This can take 24-72 hours.

Step 6: Finishing Touches

Once all tiles are in place and secured:

- Final Inspection: Walk around and check for any loose tiles, gaps, or unevenness. Make any necessary adjustments.

- Clean Up: Sweep and vacuum the floor one last time to remove any dust or debris from the installation process.

- Edge Trimming (Optional): If you have exposed edges that you want to cover, consider purchasing transition strips or bullnose edging designed for rubber flooring. These can provide a clean, finished look and prevent tripping hazards.

Special Considerations for Different Spaces

Basement Gym Flooring

Basement gym flooring often deals with concrete subfloors, which can be prone to moisture.

- Moisture Test: Before installing any rubber flooring in a basement, perform a moisture test on the concrete slab. You can do this by taping a small square of plastic sheeting to the floor for 24 hours. If condensation forms on the underside of the plastic, or if the concrete darkens, you have a moisture issue.

- Addressing Moisture: If moisture is a problem, you may need to use a waterproof sealant on the concrete before installing your rubber flooring, or consider a vapor barrier beneath the flooring. Interlocking rubber tiles with a thicker profile might be more forgiving of minor subfloor imperfections.

Commercial Gym Flooring vs. Home Gym Flooring

While the installation process is similar, there are differences in expectations for commercial gym flooring versus home gym flooring:

- Durability and Thickness: Commercial gyms often require thicker, denser rubber flooring (3/4 inch or more) to withstand extreme use, heavy weights, and constant traffic.

- Adhesive Use: Commercial installations almost always require adhesive to ensure the flooring stays put under heavy stress and movement.

- Maintenance: Commercial spaces need flooring that is exceptionally easy to clean and maintain, often favoring seamless rolled rubber or tightly fitted interlocking tiles.

Maintenance of Your Rubber Gym Flooring

Proper maintenance will extend the life of your rubber gym mats and keep your gym looking its best.

- Regular Cleaning: Sweep or vacuum your rubber flooring regularly to remove dust and debris.

- Spot Cleaning: For spills or stains, use a damp cloth with mild soap and water. Avoid harsh chemicals or abrasive cleaners, as they can damage the rubber.

- Deep Cleaning: Periodically, you can use a dedicated rubber floor cleaner or a mixture of water and white vinegar. Mop the floor and allow it to dry completely.

- Avoid Sharp Objects: While durable, sharp objects can still puncture or cut rubber flooring. Be mindful when moving heavy equipment or using tools in your gym.

Frequently Asked Questions (FAQ)

Q1: How do I cut rubber gym tiles?

A1: Use a sharp, heavy-duty utility knife and a straight edge or ruler. For thicker tiles, you may need to score the top surface first and then make multiple passes to cut through. Always wear safety glasses and gloves when cutting.

Q2: Can I install rubber gym flooring directly on concrete?

A2: Yes, you can install rubber gym flooring directly on concrete as long as the concrete is clean, dry, and relatively level. For basements, ensure there are no moisture issues.

Q3: Do I need to glue down interlocking rubber tiles?

A3: For most home gym applications, a loose-laid installation is often sufficient. However, for high-traffic areas, commercial gyms, or if the tiles feel unstable, using rubber flooring adhesive is recommended for added security and longevity.

Q4: How do I deal with gaps between rubber tiles?

A4: Ensure you are pushing the tiles together firmly during installation. If gaps persist, they might be due to temperature fluctuations or improper installation. For minor gaps, a rubber floor filler or sealant might be an option, but it’s best to ensure a tight fit during the initial installation.

Q5: What is the best type of rubber flooring for weightlifting?

A5: For weightlifting, it’s best to use thicker, denser rubber flooring. 3/4 inch or 1-inch thick rubber gym mats or interlocking rubber tiles are ideal for absorbing the impact of dropped weights and protecting your subfloor and joints.

Q6: Can I install rubber gym flooring in a basement?

A6: Yes, but you must address potential moisture issues first. Perform a moisture test and consider sealants or vapor barriers if needed. Ensure good ventilation for your basement gym flooring.

By following these detailed steps, you can confidently install your own rubber gym flooring, creating a safe, comfortable, and durable space for all your fitness endeavors. Enjoy your upgraded gym!